Tongli News

News

-

Apr 01

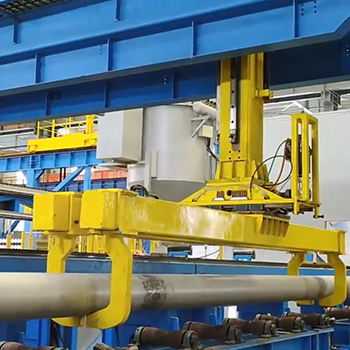

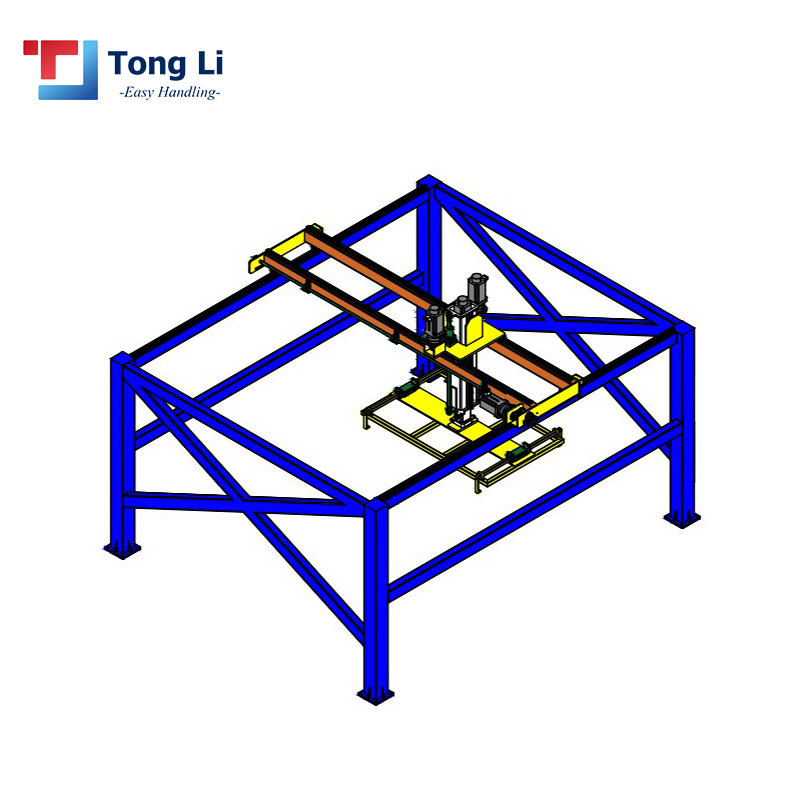

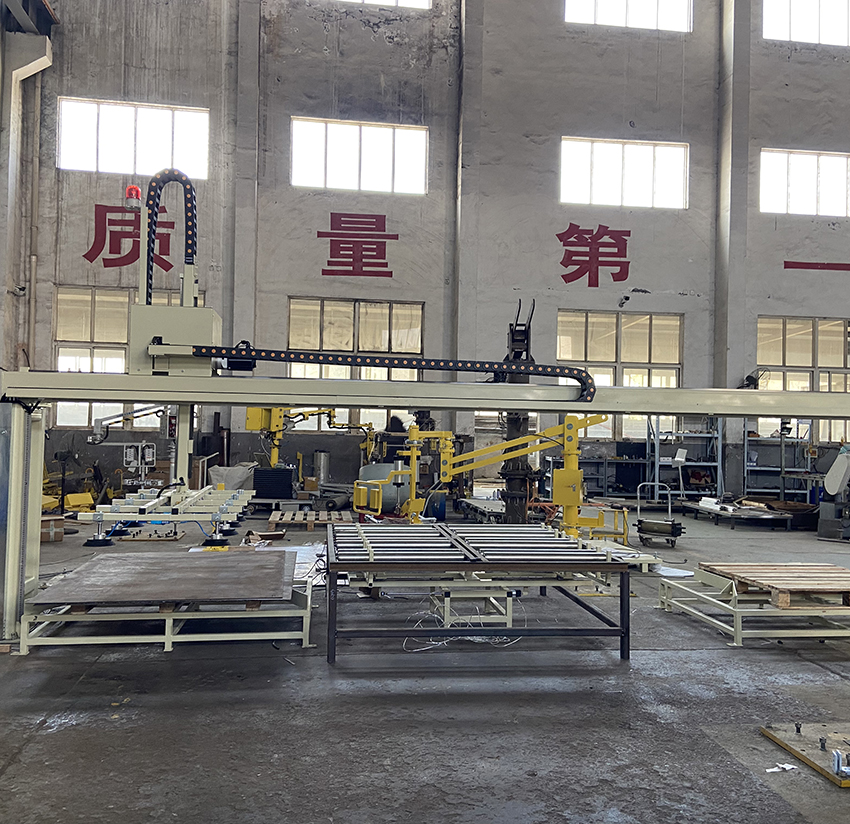

Apr 01Gantry Robots - Modular manufacturing makes operation easier

The use of gantry robots seems to be an important step taken by the enterprise factory towards full-automatic machine and full-automatic factory. The modular production of gantry r···

-

Mar 07

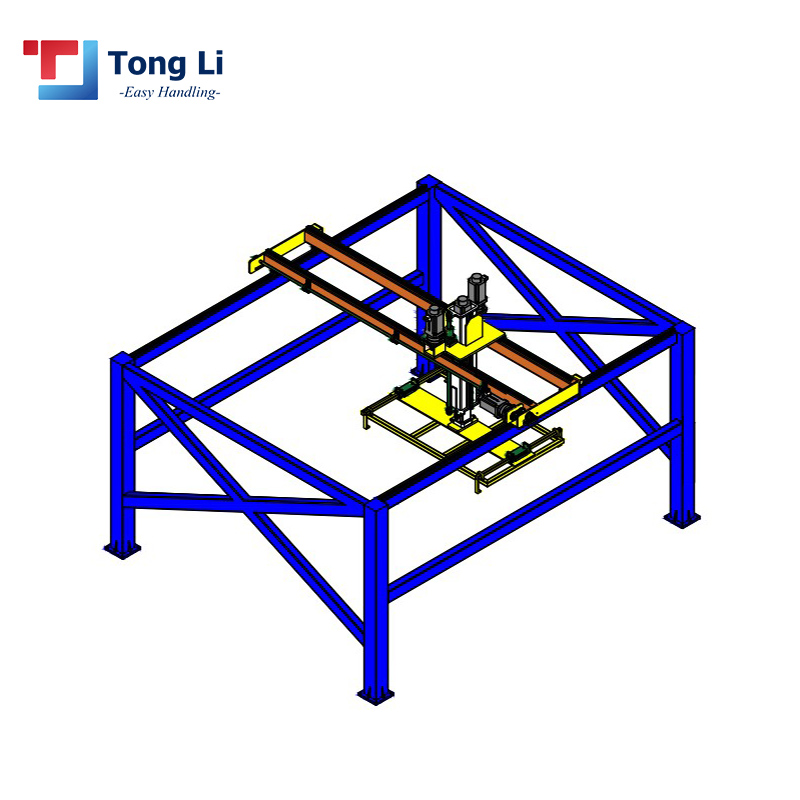

Mar 07Features of Gantry System

Gantry System is an automatic equipment that puts the whole pallet into the pallet stacking area. After the conditions and requirements are met after startup, the heavy pallet conveying device first s···

-

Feb 22

Feb 22Features Of Industrial Pneumatic Manipulator

Pneumatic technology is an engineering technology that uses the air compressor as the power source and the compressed air as the working medium to transmit energy or signal. It is one of the important···

-

Feb 18

Feb 18Advantages Of Destacker Gantry System

With the development of industrial technology, the replacement of workers by automated equipment has become the mainstream of industrial manufacturing. Among them, the gantry truss machine manipu···

-

Feb 11

Feb 11Application Of Automatic Loading And Unloading Manipulator In The Industry

What Is material handling.With the continuous development and innovation of science and technology, the development and production of robots has become a rapidly developing emerging technology in the ···

-

Sep 29

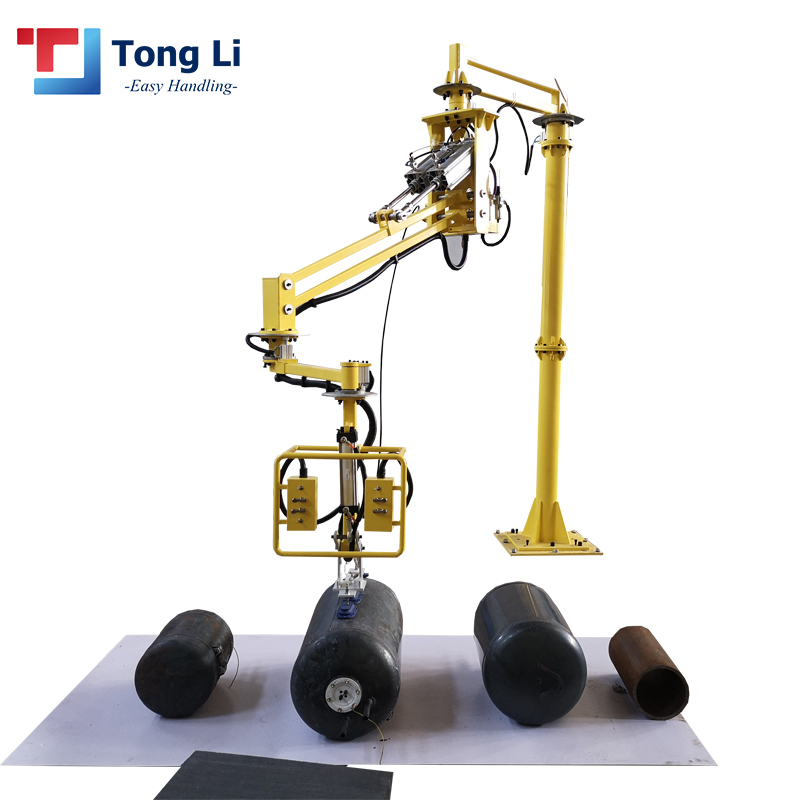

Sep 29Technical description of power assisted manipulator

A、 Purpose and characteristics1. PurposeThe column type mechanical arm (hard arm) is a power assisted mechanism for carrying heavy objects. It is widely used in the logistics system of production and ···

-

Nov 18

Nov 18The application field of automatic manipulator

Industrial manufacturing field: mainly let the automatic manipulator in the machinery manufacturing industry instead of people to complete the mass, high quality requirements of the work, such as auto···

-

Jul 20

Jul 20Advantages Of Automatic Material Handling Systems

The automatic material handling systems for loading and unloading adopts modular design, which can be combined in various forms to form multiple on-line production lines. The components incl···

-

Jul 04

Jul 04Automated Material Handling Trend And Market Planning Analysis

China is a large manufacturing country, with 39 industrial categories, 191 medium categories and 525 sub categories. It is a country with all the industrial categories in the United Nations Industrial···

-

Jul 01

Jul 01Structure Of Industrial Manipulator

Industrial manipulator is mainly composed of balance crane host, grab fixture and installation structure. The main machine of the balance crane is a device that keeps the weight in the air witho···

-

Jun 27

Jun 27Technical Characteristics Of Robotic Palletizer

Characteristics of industrial robotic palletizer according to the definition of the International Federation of Robotics (IFR), robots are divided into industrial robots for industrial production···

-

Jun 23

Jun 23Application Of Lifting Manipulators

The lifting manipulator is safe, efficient and reliable. It can work in a variety of environments, such as flammable, explosive, high temperature and high radiation. The equipment is light in weight, ···

-

Jun 14

Jun 14Main Technical Parameters Of The Manual Manipulator

The main technical parameters of the general manual manipulator are as follows:1) Control force (also known as arm force or load), that is, the weight of grasping and holding the workpiece, the o···

-

Jun 08

Jun 08Composition and advantages of industrial manipulator?

Power assisted manipulator, also known as power assisted arm, mechanical arm, balance booster, balance crane, power assisted transfer machine, labor-saving sling, labor-saving grab, labor-saving handl···

-

May 31

May 31What is a vacuum lifter

With the development of economy and the progress of science, all industries have made continuous progress. In order to buy a vacuum lifter with better quality and reasonable price, we need to hav···

-

May 17

May 17Composition of machine loading and unloading

The application of intelligent equipment in industrial field is becoming more and more common. In particular, automated production enterprises need the addition of some intelligent equipment. Truss ro···

-

May 12

May 12Analysis On Positioning Accuracy Of Truss Manipulator

Positioning accuracy of truss manipulator as the truss manipulator belongs to high-precision equipment, we need to carry out precision calculation and checking calculation for the truss manipulator du···

-

Apr 27

Apr 27How To Maintain The Robot Manipulator If It Is Not Used For A Long Time?

The robot manipulator is an important part of precision machine tool. In order to ensure the speed, accuracy and service life of linear slide module, it is necessary to operate it correctly to prevent···

-

Apr 24

Apr 24Advantages Of Gantry Style Robots In Grasping And Handling

At present, with the more and more extensive application of various manipulators, the production, processing and production lines in many workshops gradually begin to choose equipment to replace manua···

-

Apr 19

Apr 19What Can Packaging Gantry Robots Do Instead Of Manual Work

The Packaging Gantry Robots can imitate human hands to complete many difficult actions to achieve different operations. It can carry and stack fixed items, and can also grasp and assemble spare parts ···

-

Apr 11

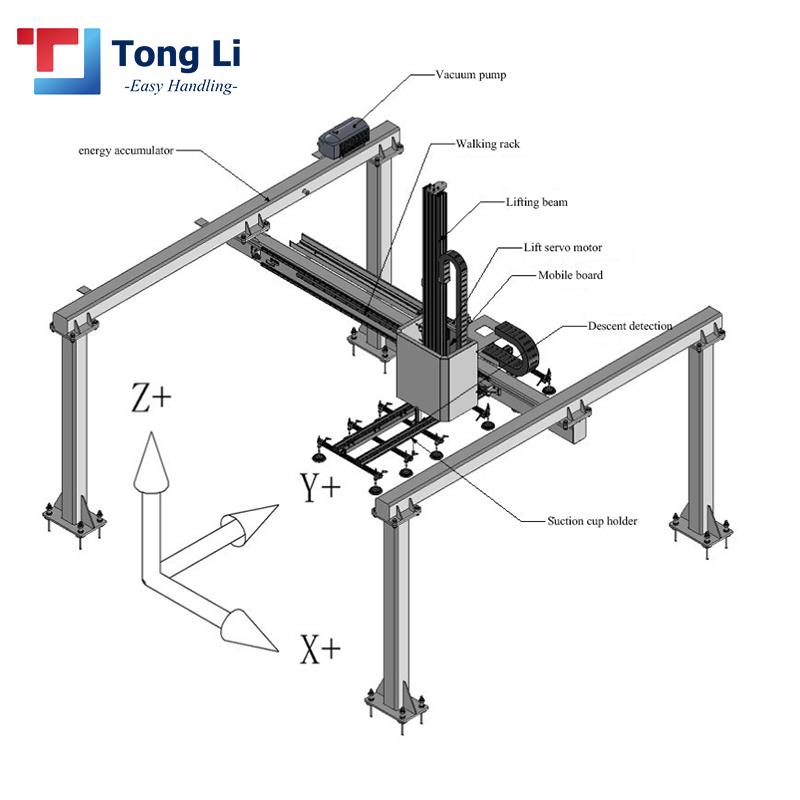

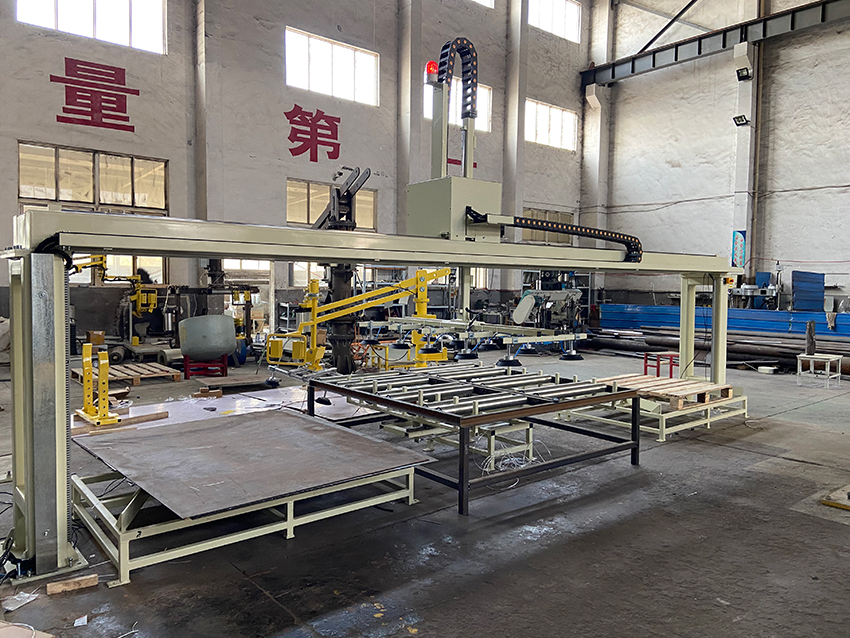

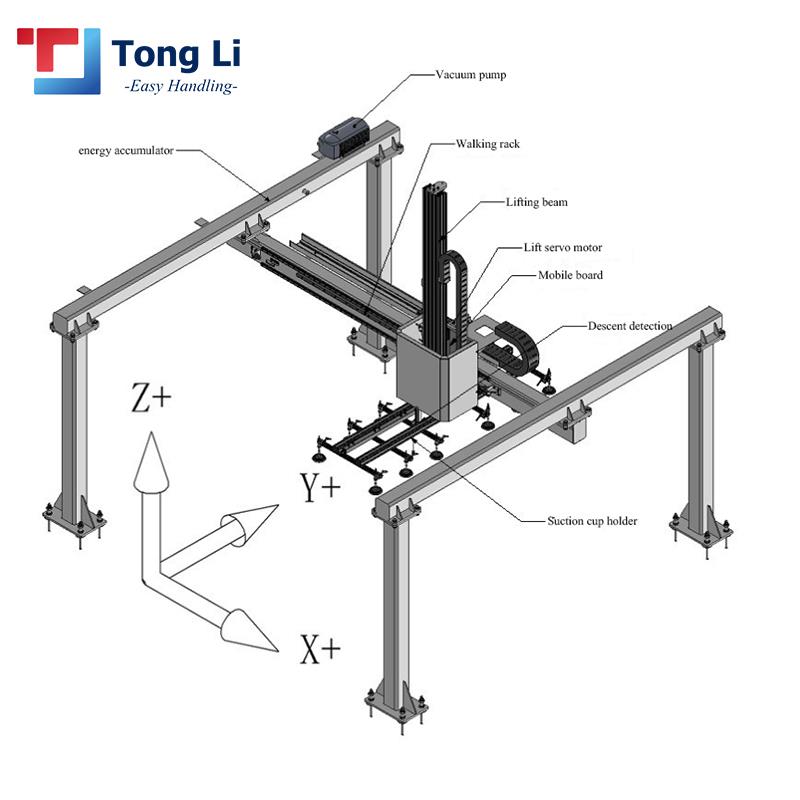

Apr 11Manual Of Gantry System

The gantry system, also known as the automatic machine loading and unloading, uses profiles or square steel as the main frame, inlaid with linear sliding guides and gear racks. The cross-sectional sha···

-

Apr 08

Apr 08Common Safety Devices Of Automated Material Handling Systems

Automated Material Handling Systems is a fully automatic industrial equipment produced by workpiece processing, so its safety setting is relatively high. On the one hand, the safety device of&nbs···

-

Mar 31

Mar 31Industrial Application Of Gantry Robots

The definition of gantry style robots is the user customized and unique automation system integration equipment. It is assembled from the unit equipment manufactured by adopting the unified industrial···

-

Mar 28

Mar 28Introduction To Pneumatic Industrial Handling Manipulator

The hard arm (ABS) pneumatic industrial handling manipulator is suitable for safely and efficiently grasping any object with different shapes and shapes. The grasping weight range is 10kg-500kg. ···

-

Mar 23

Mar 23What Is An Automatic Manipulator

What is automated material handling,make an easy about materials handling.Automatic manipulator is an automatic operating device that can imitate some action functions of human hands and arms to grasp···

-

Mar 18

Mar 18Application Of Pneumatic Manipulator In Industrial Manufacturing

In order to save time and labor in all walks of life and improve work efficiency, Lift Assist Devices appear. Industrial Pneumatic Manipulator can make the work of all industries easier and labor···

-

Mar 14

Mar 14Advantages And Application Of Balance Crane

The balance crane is a kind of auxiliary machinery which is convenient for human operation, has a relatively single working place and a relatively fixed working position. It is widely used in the asse···

-

Mar 11

Mar 11Features Of Post Mounted Jib Crane

The Post Mounted Jib Crane is a kind of mechanical equipment that uses the principle of four-bar linkage mechanism. It is a pair of balance system composed of load and balance breeding structure ···

-

Mar 02

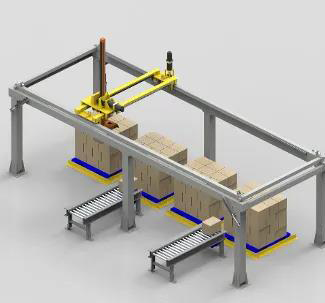

Mar 02The Working Principle Of Automatic Palletizing And Transfer Systems

Automatic palletizing and transfer systems refers to the automatic palletizing equipment suitable for chemical, petroleum, paint, grease, pigment and other enterprises.working principleThe workpi···

-

Feb 24

Feb 24Classification And Application Of Balance Crane

The balance crane is a new type of material hoisting equipment. It uses a unique screw lifting mechanism to lift heavy objects and replace human labor to reduce labor intensity.Basic classificationThe···

-

Feb 15

Feb 15Precautions For Using Loading And Unloading Manipulator

1. Pay attention to the clamping force of the manipulator: When using the loading and unloading manipulator, you need to select the appropriate clamping force according to the different types of mater···

-

Jan 11

Jan 11How to maintain truss manipulator

1. Each guide rail surface shall be clean and smooth every day. The robot truss manipulator with active smooth system shall regularly check and clean the active smooth system, check the oil quantity, ···

-

Dec 23

Dec 23How To Operate The Manipulator Correctly

Nowadays, more and more enterprises choose to use manipulator for palletizing and handling. So, for novice customers who just bought a manipulator, how should they use the manipulator? What should we ···

-

Sep 29

Sep 29Advantages and characteristics of power assisted manipulator

The manipulator adopts the balance principle of force. Through the air pressure generated by the air compressor, the materials are suspended during lifting or falling, reaching 0 gravity. The buttons ···