Technical description of power assisted manipulator

A、 Purpose and characteristics

1. Purpose

The column type mechanical arm (hard arm) is a power assisted mechanism for carrying heavy objects. It is widely used in the logistics system of production and assembly of chemical industry, electronics, automobile, household appliances, food and beverage, etc. When the work station is limited or uncertain, it will easily and accurately transfer the load for you. It greatly reduces the labor intensity of the operator, improves the work efficiency, and is easy to realize the large-scale and automation of production. It is a powerful tool to cooperate with automatic production.

2. Features

It can carry heavy objects within a certain radius;

Large height stroke and handling weight;

The transportation between fixed places is more convenient and free;

The fixture can realize the turnover function.

B、 Working principle and structure

1. Working principle

The column manipulator adopts the lever principle, uses the cylinder to drive the near end of the lever, and the far end of the lever can lift heavy objects. The pressure in the cylinder is set by the precision pressure reducing valve and automatically stabilized to keep the balance between the force applied by the cylinder and the tension of the weight. When the operator controls the rise or fall with external force, the balance state is destroyed and the balance is automatically maintained again. Therefore, the process of moving the weight with little control force is achieved.

In the control mode of column hard manipulator, multi load operation and mutual conversion of empty and load are realized through multiple control of pressure; The system provides timely protection in case of circuit pressure fluctuation and gas cut-off; The load can be relieved only when the weight reaches the station and is placed stably, so as to avoid accidents caused by misoperation.

2. Structure

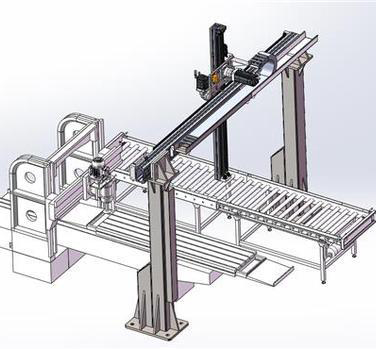

The structure of the mechanical arm is shown in the figure below, which is installed by column.

It includes the following parts: (1) the column part adopts high-strength structure and can bear the whole weight; (2) The main control box is divided into two parts. The power drive, anti impact device and pneumatic control system of the manipulator are concentrated in this box; (3) Main boom; (4) From the force arm part; (5) The coupling and braking mechanism of the slave arm; (6) Operating handrail; (7) Fixture part. According to different requirements, the master-slave force arm can be adjusted accordingly.

C、 Fixture mode

Pneumatic clamping type

Clamping fixture is the most widely used fixture, which is characterized by wide application range and low failure rate

D、 Operating procedures

Description of control panel buttons and indicators

The control panel of the column manipulator is provided with the following buttons: a clamping knob; A joint lock button; A release button; No load / load transfer button

Joint lock knob: rotate the joint limit at the column;

Clamping button: press the clamping button, and the fixture will clamp the workpiece

Release button: after moving the workpiece to the specified position, press the release button to put down the workpiece.

No load / load conversion button: clamp the workpiece, switch the no load conversion button to the load gear, lift the workpiece, and move the workpiece in place. Switch the no-load conversion button to the no-load gear, release the button and put down the workpiece.

By operating the control panel handrail, the object can move within the range of 1 ´ 360 ° (main arm rotation) and 2 ´ 270 ° (other rotation): the maximum rotation radius can reach 1500mm. Through the force balance mechanism, the stroke of the manipulator in the height direction can reach 1500mm, and the distance between the limit station and the ground is related to the installation height.

E、 Precautions

When grasping heavy objects, it must be determined that the air supply pressure of 0.5 ~ 0.8MPa can be reached, but the external air source shall not be less than 0.6 MPa;

The design has ensured sufficient allowance in the height direction, and the work does not have to be carried out in the limit station, so do not often let it move in the limit station;

Regular inspection and maintenance shall be carried out for connection and lubrication links;

All pneumatic valves and components have been debugged before leaving the factory. The air circuit cannot be changed at will. The adjustment should be guided by the professional personnel of our company;

When the balancer is in use, it is strictly prohibited to stand under the heavy object and the master-slave force arm to prevent accidents;

All rotating joints are rotating during use. Do not touch them with your hands to prevent injury. The maintenance shall be carried out under shutdown;

After the work is completed, please lower the clamp claw to the lowest position and avoid the rear brake of the surrounding personnel or objects, so as to prevent the clamp from falling slowly and hurting the surrounding objects or standing personnel after the air circuit is suddenly cut off or after work;

Turn off the air supply after work.

F、 Routine maintenance

Drain the water in the air tank and pressure regulating filter regularly

Often check the air pipe connector to see if there is air leakage.