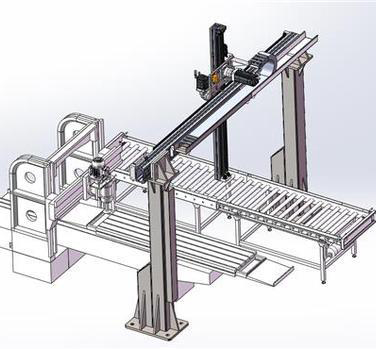

Composition of machine loading and unloading

The application of intelligent equipment in industrial field is becoming more and more common. In particular, automated production enterprises need the addition of some intelligent equipment. Truss robot is the product born under this situation, which not only saves a lot of labor costs, but also improves the production efficiency, which can be said to kill many birds with one stone. However, when using this kind of equipment, we also need to know more about the machine loading and unloading in order to make better use of it to do things for us. What is the composition of machine loading and unloading? Let's take a closer look.

Generally speaking, the structure of machine loading and unloading is relatively simple, including execution system, driving system, control system and azimuth detection system.

1、 Execution system

The execution system of machine loading and unloading undertakes the main operation tasks. It has many components, such as manipulator, wrist, arm, column and so on.

1. Manipulator, that is, the part directly involved in processing and producing goods, usually comes into contact with products.

2. As the connection between the manipulator and the arm, the wrist can adjust the orientation of the contacted goods.

3. The arm is also a key component in the execution system. It and the column are the backbone of the whole operation task.

4. Needless to say, the base is the fundamental part of the whole execution system. Whether manipulator, wrist, arm and other movements are completed based on the base.

2、 Drive system

This is the driving device for the machine loading and unloading to perform production and processing tasks. It consists of power, conditioning and auxiliary equipment. Some of our common driving methods include hydraulic, pneumatic and mechanical driving.

3、 Operating system

When running the machine loading and unloading, the function of the control system is to assign the manipulator to complete the required actions.

4、 Azimuth detection system

This part is to control the movement direction of the manipulator and feed back the movement effect through various detectors, so as to realize continuous fine-tuning, so that the manipulator can reach the specified position and contact the processed and produced products, so as to ensure that the manipulator can accurately complete the production and processing tasks.

In addition to the above hardware composition, there is also a software part, that is, the program. Through the program to guide the manipulator to complete the corresponding task. All the actions of machine loading and unloading need to be controlled by program, so as to ensure the sequence of operation of each component and complete the task in an orderly manner.

We can see that the manual processing and production operations have sequence, simple work and high repeatability. However, it is not easy for truss robot to replace manual operation. It needs to combine software and hardware to achieve the goal.