Features Of Industrial Pneumatic Manipulator

Pneumatic technology is an engineering technology that uses the air compressor as the power source and the compressed air as the working medium to transmit energy or signal. It is one of the important means to realize various production control and automatic control.

The industrial pneumatic manipulator works through pneumatic transmission, the pressure is low, the operation is simple and easy, and the handling is convenient. Generally, the compressed air can be stored in the air storage tank, and even if there is a sudden power failure, the process flow will not be interrupted suddenly.

As a kind of manipulator, industrial pneumatic manipulator is widely used because of its advantages of simple structure, light weight, rapid action, stability, reliability, energy saving and no environmental pollution.

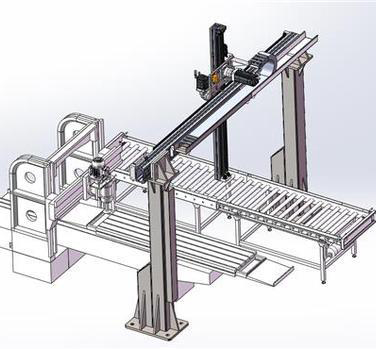

The pneumatic manipulator has strong versatility. The mechanical arm adopts the air negative pressure suction cup or the clamping type, which can realize the rotation movement of the wrist. According to the requirements of grasping the workpiece, the arm has three degrees of freedom, namely, the arm's extension, left and right rotation, and up and down lifting. sports. The slewing and lifting movements are realized through the column.

The lateral movement is the lateral movement of the pneumatic manipulator. Various movements of the industrial manipulator are realized by the cylinder. Due to the rapid action, sensitive response, small resistance loss and leakage of the pneumatic transmission system, the cost is low, and it has a certain bearing capacity. Features such as sufficient workspace and automatic positioning in any position. The control system composed of pneumatic components is only suitable for simple processes and small products. Because of the lack of positioning accuracy, it cannot achieve high-precision positioning at high speed.