Common Safety Devices Of Automated Material Handling Systems

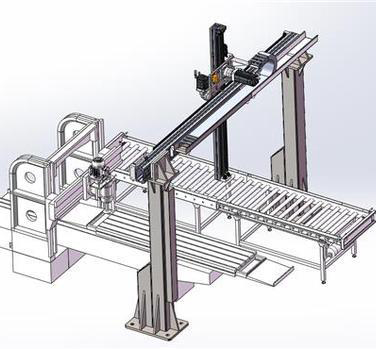

Automated Material Handling Systems is a fully automatic industrial equipment produced by workpiece processing, so its safety setting is relatively high. On the one hand, the safety device of automatic loading and unloading can make the manipulator closely cooperate with relevant NC equipment to complete the production of a series of complex workpieces. On the other hand, it not only improves the working efficiency of the equipment, but also provides a great guarantee for the safety of equipment operation. So what are the safety devices of this kind of equipment? Let's learn about them together.

1. Air cut-off protection safety device of automated material handling systems

The gas cut-off protection safety device is the power and emergency device in the automated material handling systems . This kind of device is mainly composed of corresponding valves and gas tanks. On the one hand, it is to provide a certain degree of stable power for the operation of the automated material handling systems, on the other hand, it is to take preventive measures to prevent the gas cut-off phenomenon of the equipment during operation; The device mainly adopts relevant buttons to control the equipment professionally during equipment operation.

2. Limit bearing protection device of automated material handling systems

The workpiece controlled by the automatic loading and unloading is often large in volume and weight, and the limit load-bearing protection device can professionally control the operation process of the automatic loading and unloading on the overweight workpiece, so as to prevent the equipment damage caused by the excessive grasping of the workpiece by the automated material handling systems.

The main protection modes of such devices are: when the manipulator operates the workpiece beyond the specified range of the equipment, the limit load-bearing protection device can alarm the equipment. If the weight of the operated workpiece reaches the critical value of equipment operation, the protection device will automatically close the safety valve of the automated material handling systems., etc.

3. 3. Low voltage alarm device of automated material handling systems

At present, the most commonly used automated material handling systems in industrial processing is the air pressure automatic loading and unloading. The main power of this kind of automated material handling systems is the corresponding air pressure device, and the low-pressure alarm device is to monitor the relevant air source of the automatic loading and unloading in real time. When the air source of the automated material handling systems is abnormal, the low-pressure alarm device can deal with the abnormal information in time, so that the management personnel of the equipment can take measures in time, The common safety device of automated material handling systems also includes braking device. The main function of this device is to professionally control the operation and end stage of the automatic loading and unloading. At the same time, this device can control the rotation and position fixation of the manipulator to avoid the automated material handling systems falling off or loosening due to improper operation of the equipment.