How To Maintain The Robot Manipulator If It Is Not Used For A Long Time?

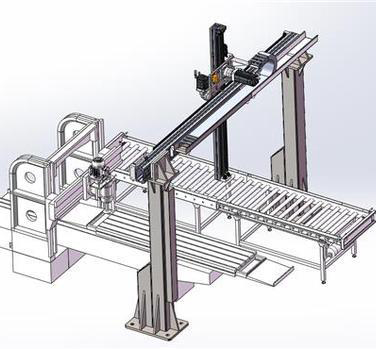

The robot manipulator is an important part of precision machine tool. In order to ensure the speed, accuracy and service life of linear slide module, it is necessary to operate it correctly to prevent abnormal wear. If the routine maintenance work is done well, the robot manipulator can maintain good performance for a long time, prolong the service life, and find and eliminate hidden dangers in time. Especially when the robot manipulator is not used for a long time, we need to pay more attention to the usual maintenance.

When the robot manipulator is not used for a long time, if it is not carefully maintained, it will cause the decline of accuracy and speed, the shortening of service life or other corrosion, rust and other faults when it is used suddenly. Normal maintenance includes the following aspects:

1. When the DC commutator is disabled, the performance of the DC commutator cannot be matched with that of the robot manipulator, so as to avoid the damage to the DC commutator.

2. In the rainy season or in the environment with high relative humidity, the linear module should be powered on regularly. When the motor is not running, that is, when the machine tool is locked, let it idle, and use the heating principle of electrical components to disperse the moisture in the linear module, so as to ensure the stability and reliability of its performance. In addition, the conventional power supply can ensure the charging demand of the backup battery, but the battery voltage should be checked frequently. If it is too low, it needs to be replaced immediately to prevent data loss caused by power failure.

3. For the deactivated robot manipulator, anti rust oil and lubricating oil should be used regularly to prevent rust or corrosion and avoid failure in use.

The precision robot manipulator has very small friction resistance, so it only needs very small driving force to move the load. Low frictional resistance helps to reduce the heating effect. Therefore, compared with the traditional sliding mode system, the friction resistance of the robot manipulator is reduced and the accuracy can be maintained for a long time.