The Working Principle Of Automatic Palletizing And Transfer Systems

Automatic palletizing and transfer systems refers to the automatic palletizing equipment suitable for chemical, petroleum, paint, grease, pigment and other enterprises.

working principle

The workpiece on the flat plate meets the first layer of workpieces required by the pallet, and the flat plate and the workpiece move forward until the vertical surface of the pallet. The upper stopper bar descends, and the other three-way positioning stopper starts to clamp, and the plate is reset at this time. Each workpiece is lowered to the pallet plane, the pallet plane is 10mm away from the bottom surface of the plate, and the pallet is lowered by one workpiece height. Repeat the above until the pallet stacking reaches the set requirements.

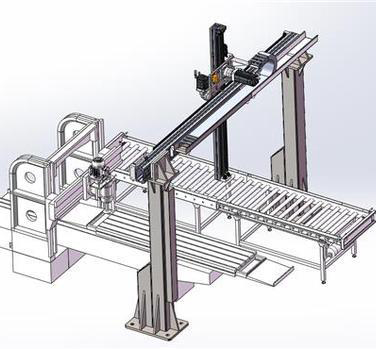

Automatic palletizing and transfer systems is composed of controller, automatic pallet loading equipment, automatic separation device, moving beam vacuum lifting manipulator, heavy pallet conveying device, etc. It is a high-tech product integrating machine and electricity. Medium and low-level palletizers can meet the production needs of medium and low output. According to the required grouping method and number of layers, it can complete the stacking of various products such as material bags, plastic blocks, and boxes. The optimized design makes the stack shape tight and neat.