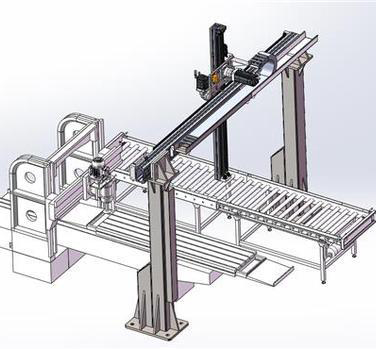

Manual Of Gantry System

The gantry system, also known as the automatic machine loading and unloading, uses profiles or square steel as the main frame, inlaid with linear sliding guides and gear racks. The cross-sectional shape of the refined profile as the moving frame and carrier is optimized through finite element analysis, and the excellence in production ensures its strength and straightness. The gantry system effectively improves the working environment, provides digitalized, informatized, and unmanned management of parts processing, reliably guarantees product quality, greatly improves labor productivity, and liberates workers from heavy manual labor. come out and bring modern manufacturing technology to a whole new level.

The gantry system is a automatic machine loading and unloading based on the right-angle X, Y, Z three-coordinate system, which can adjust the position of the workpiece or realize the trajectory movement of the workpiece. Its control core is coordinated and controlled by industrial controllers (such as PLC, motion control, single-chip microcomputer, etc.), and is processed by various hydraulic cylinders and air cylinders. The whole automatic loading and unloading process includes five parts: workpiece conveying, manipulator reclaiming, chuck loading and unloading, manipulator feeding and sending parts to the next process. Among them, the part that conveys the workpiece and the parts are sent to the next process is performed in parallel with other parts, and the CNC machining is performed in parallel with the gantry system reclaiming and feeding part and the CNC machining.