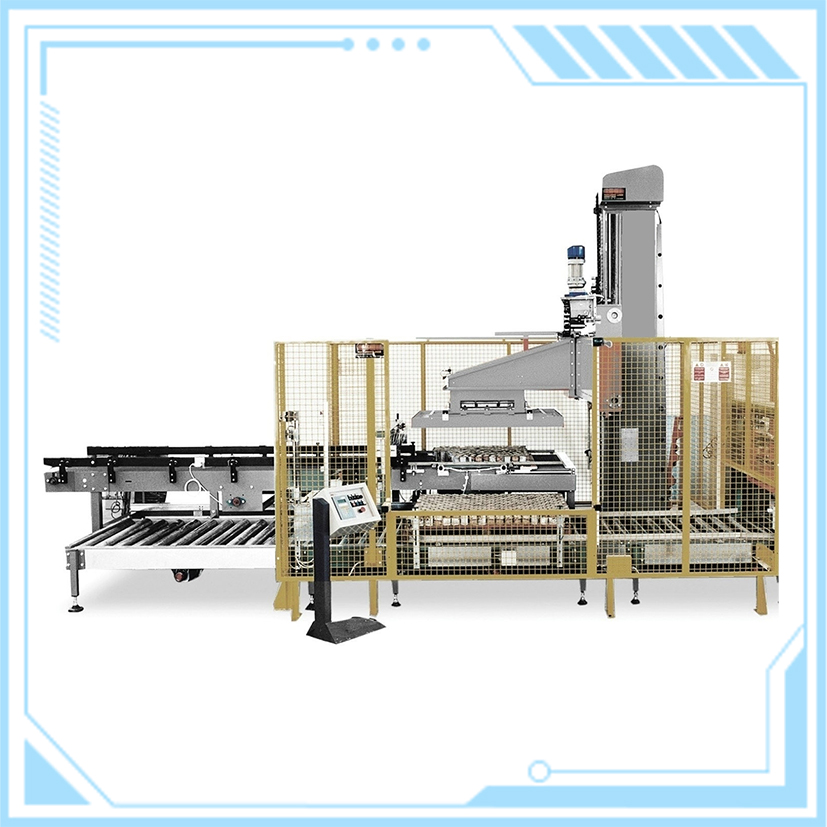

Column robot palletizer

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Among the many robot palletizers, the column-type robot is a palletizer equipment favored by many small and medium-sized enterprises. It not only has a small size and a small footprint, but also has a comprehensive combination of palletizing efficiency, equipment functions, equipment quality, and price. The factors are very suitable for the status quo that small and medium-sized enterprises have moderate output and urgently need machine replacement. What are the equipment characteristics and working principle of the column-type robot palletizer? Below, Tengyang Susu briefly introduces

Features

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

The column robot adopts the robot control system to realize the linear interpolation from point to point, which can make the movement smooth and smooth. The teaching pendant controls the movement of the industrial robot through monitoring and display functions, which enables the operator to smoothly realize the teaching control of the positioner movement. The stack type is pre-stored in advance and can be flexibly added in the later period. The grouping method and layer are required when working. Count, complete the palletizing of the bag products.

The column-type robot palletizer can work 300-600 times per hour, has 4 degrees of freedom, and is flexible in operation. It can load 100KG and the body weight is about 1.5t. It can be set with single or double jaws according to site requirements to replace various grabs. Type, splint type, adsorption type gripper, can box and palletize finished products of various shapes such as boxed, bagged, boxed, filled, bottled and so on. The operation is simple, just set the marshalling method and the number of layers to complete the stacking of the bag products. The equipment is widely used in feed, fertilizer, grain and oil, chemical, beverage, food and other production enterprises.

working principle

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

The operating process of the column robot palletizer is to send the packaged materials to the palletizing area through the conveyor for positioning. The column robot moves the fixture to directly above the material positioning through the cooperation of each axis. When the material positioning signal is sent out, the fixture movement is controlled by the servo motor to move downward, that is, the Z axis moves downwards. When the material clamped by the fixture is reached, the Z axis stops descending, the fixture opens, the material is clamped, and the Z axis servo motor reverses to raise the fixture to a safe height. The customer preset program sends the material to the top of the palletizing position, and the Z axis descends to make the material reach the placement point. At this time, the clamp opens, and the material is palletized into the specified position. Repeat the above actions. After the entire drag is palletized, the buzzer Alarm, reminding that palletizing has been completed. The forklift transports the stacked pallets away, puts them in a new pallet, and reciprocates again.

The column robot palletizer adopts full servo drive, excellent material selection, simple and reasonable equipment structure, easy operation and maintenance, stable and reliable operation, flexible action, high operation precision, large range, low comprehensive application cost, and can achieve cost effective utilization. There are few components, low maintenance cost, low power consumption, low failure rate, stacking type and stacking layer number can be set arbitrarily, the stacking type is neat, will not collapse, and it is convenient for storage and transportation. This equipment is widely applicable to the needs of carton, bag, filling, barrel, box, bottle and other shapes of finished products forpacking and palletizing of feed, chemical, food and beverage, and grain production enterprises to carton, bag, filling, barrel, box, bottle and other shapes of the finished products for packing and palletizing needs.