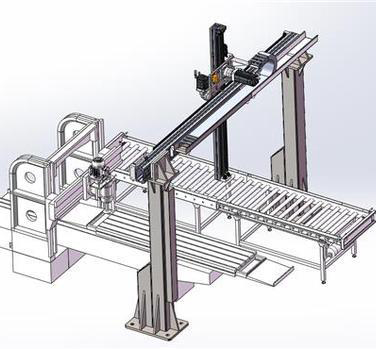

Technical Characteristics Of Robotic Palletizer

Characteristics of industrial robotic palletizer according to the definition of the International Federation of Robotics (IFR), robots are divided into industrial robots for industrial production environment and service robots for human non productive activities. Industrial robotic palletizer is a kind of "automatic positioning control, reprogrammable, multi-functional and multi degree of freedom manipulator, capable of handling materials, parts or tools for completing various operations". Its main technical features can be summarized as follows.

1) Programmable. Industrial robotic palletizer has an independent control system, which can change its action and behavior by programming, and has the flexibility to adapt to the changes of working environment.

2) Personification. Most industrial robotic palletizer have human like lumbar rotation, large arms, small arms, wrists, claws and other components in the mechanical structure, and are controlled by their controllers. The intelligent industrial robotic palletizer is also equipped with sensors simulating biology, such as sensors simulating sensory contact, force, load and light; Image recognition sensor simulating vision; Analog auditory sound, voice sensors, etc., which have a certain ability to adapt to the environment.

3) General. Most industrial robotic palletizer have certain versatility to perform different tasks. For example, they can perform different tasks by replacing the end manipulator (claw, tool, etc.) of the hand.