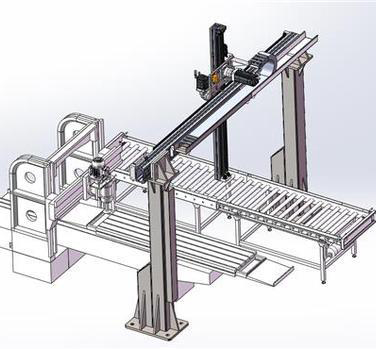

The Gantry Robots For Automatic Palletizing

The gantry robots is a highly packaged all-in-one machine, which combines the robot body, arms, rails, columns, gripper system, control cabinet, operation panel,

The man-machine interface, silo, turning table (optional), sampling station (optional), etc. are packaged together to form a standard robot automatic loading and unloading unit body, which can realize the overall installation, debugging and transportation.

Features of TL-ZX series gantry robots

■ All equipment units are modularized and run according to the CPU, with higher precision and faster installation;

■ Fool-style operation and maintenance, realizing multi-connection, fast and accurate adjustment, and the training was on duty at the time;

■ Wide versatility, one machine can be used for multiple purposes, allowing users to save a lot of equipment costs;

The core accessories are imported from big brands, with super long service life;

■ It can realize "unmanned" machining automatic production line, liberate manpower to the greatest extent, and enable users to save labor costs.

The purpose of using the truss-type online robot:

1. The use of manipulators instead of manual operations can realize one person and N sets of CNC machine tools, saving more than 80% of labor;

2. Use manipulators instead of manual operations to prevent industrial accidents and reduce the burden on enterprises;

3. Improve the production efficiency by 300%, and the manipulator can achieve 24-hour uninterrupted operation;

4. Automatic production, higher precision, to ensure stable workpiece size.