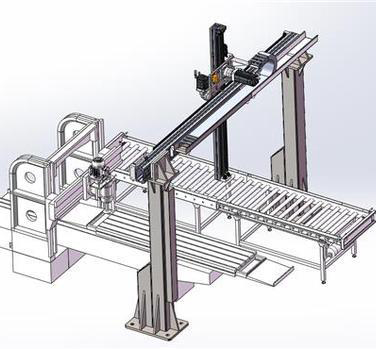

Transfer Systems For Material Handling And Packaging

Transfer Systems Features

1. Efficient — The axes run in a straight line at a very high speed, and the servo motor can be used for quick response;

2. Stable — Minimal repeatability error, up to 0.05mm;

3. High intensity — 24 hours of work, no need to eat, sleep, smoke, etc.;

4. High precision — The positioning accuracy can reach 0.03mm (based on the production cost, the positioning accuracy can be appropriately enlarged according to the working conditions);

5. High cost performance — Compared with joint robots, its load weight is large and its production cost is low, which is suitable for the basic national conditions of "China's intelligent manufacturing";

6. Simple operation — Based on the Cartesian coordinate system, its motion parameters are relatively simple.

Transfer Systems Advantages:

1. High safety. Use human hands to enter the mold to take the product. If the injection molding machine fails or the mold is closed by mistake, there is a danger of pinching the worker's hand. The use of a manipulator can ensure safety.

2. Save labor. The manipulator takes out the product and places it on the conveyor belt or the receiving table. Only one person is required to take care of it or one person can watch two or more injection molding machines at the same time, which can save labor. Factory planning is smaller, more compact and refined.

3 CNC lathe manipulator. Extend the service life of the manipulator. People need to open and close the safety door frequently to take out the product, which will shorten the life of some parts of the injection molding machine or even damage it, affecting production. Using a manipulator does not require frequent opening and closing of the safety door.

4. The CNC lathe manipulator reduces the defect rate of the product. The newly formed product still has unfinished cooling, and there is residual temperature. Manual removal will cause hand marks and uneven manual removal force. There are uneven variations of the product. The manipulator adopts a patternless gripper to exert even force, which greatly improves the product quality.

5. Prevent mold damage. People sometimes forget to take out the product, and mold clamping will cause mold damage. If the manipulator does not take out the product, it will automatically alarm and stop, which will never hurt the mold.

6. The CNC lathe manipulator saves raw materials and reduces costs. The undetermined removal time of personnel will cause product shrinkage. Variation, because the manipulator removal time is fixed, the quality is stable.

7. The use of CNC lathe manipulators largely overcomes the inertia of manual labor and can accurately calculate the daily output and delivery time. The use of manipulators can increase the competitiveness of enterprises, and it is the biggest trend in the future.